Scope of Work:

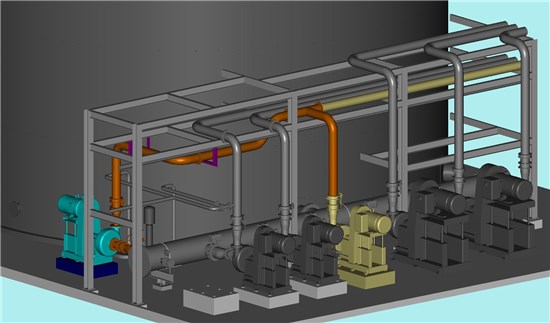

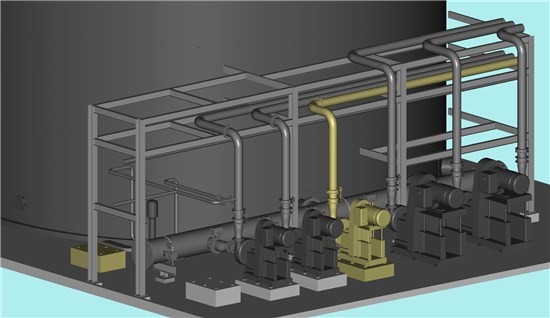

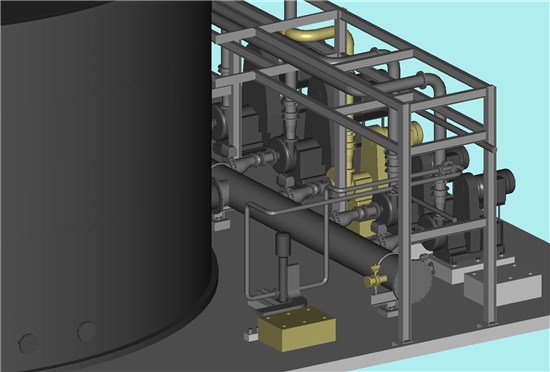

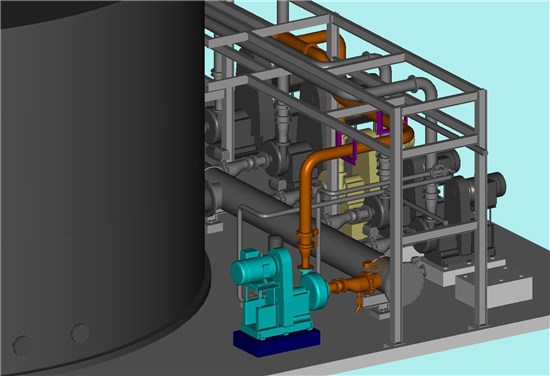

Provide a design, of a new pump and pipework, to provide a standby system for the GEHO flush water piping system.

The current GEHO flush water system was supplied by a single Warman pump. This did not allow for the maintenance of this pump other than during a full shutdown of the Ore Processing Facility. Therefore there was a need for a standby pump to be designed to fit into the current system.

Goal:

By providing a standby pump, that can operated while the duty pump is repaired, it removes the need to shut down the Processing Facility.

The location of the existing duty pump and piping was such that there was no room close by for the new standby pump to be installed.

Design Constraints:

The new standby pump needed to be located as close as possible to the duty pump and the flush water piping system. Space limitations in this area, for a tie in of the standby pump piping to the existing header, dictated the location of the new pump.

PEA identified the only available location for the new pump was a space where a redundant process water pump was located. The existing plinth and header stub piping was designed for a smaller pump and would need to be removed and replaced.

Proposed Design:

The proposed design was to install a new Warman pump of the same size as the existing duty pump. Due to the header being “live” while the tank was full of water the new suction piping had to be designed to allow for a “hot tap” into the header. The new plinth had to be designed to accommodate the new pump and also avoid the existing cable conduits.

The new standby pump and most of the piping were installed prior to a shutdown. This left only the tie in spool between the two discharge lines to be completed during the shutdown.