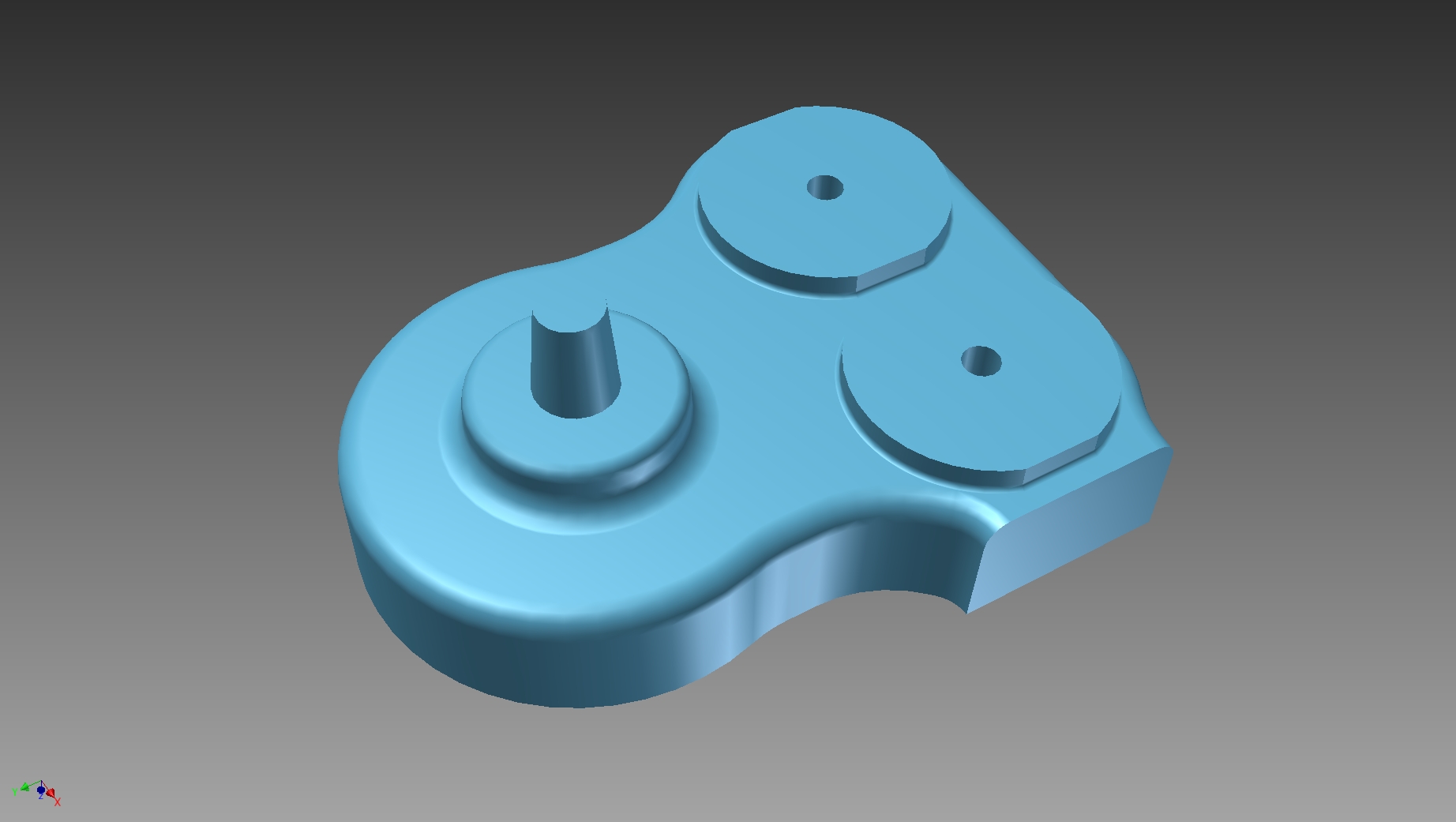

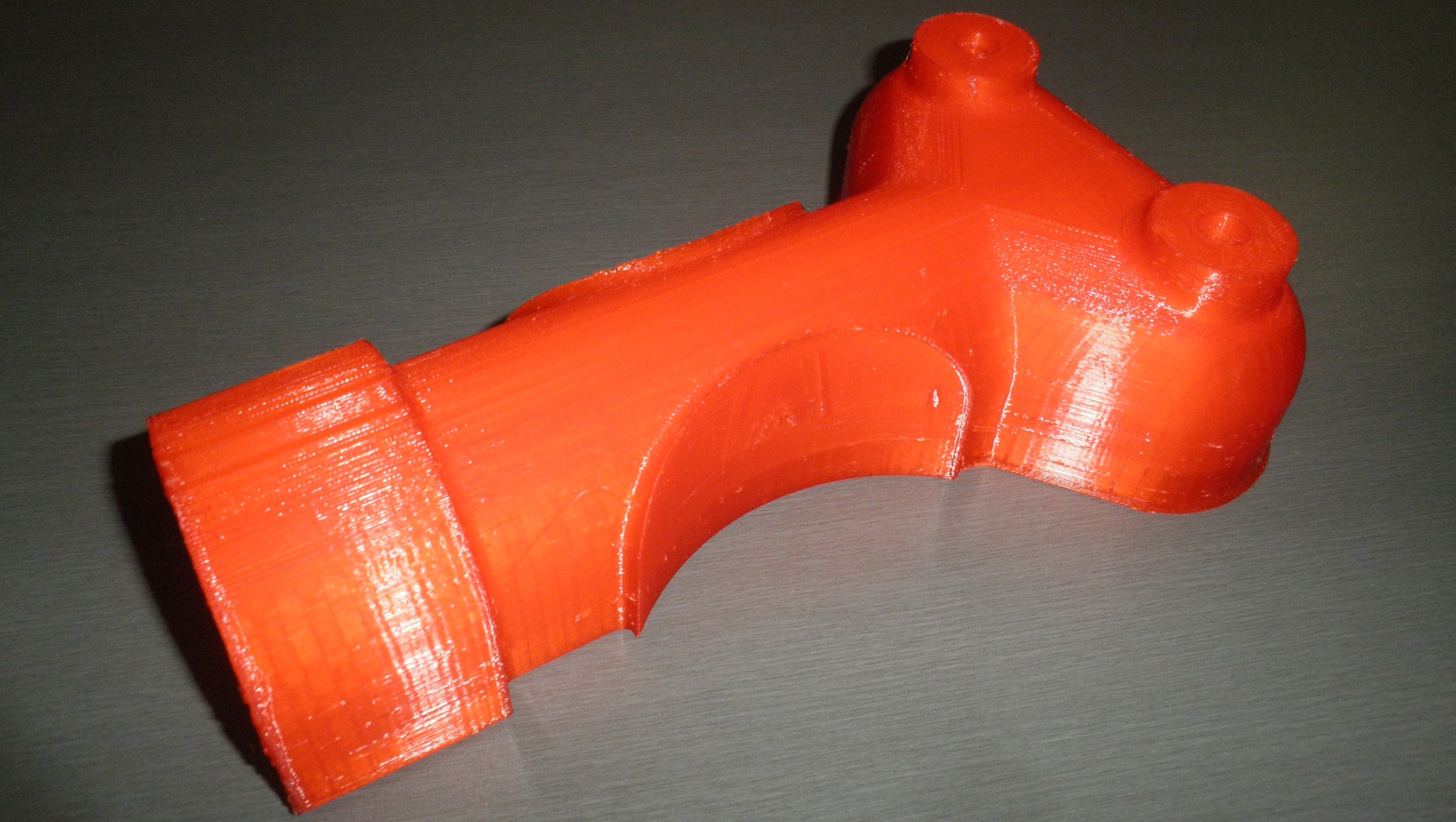

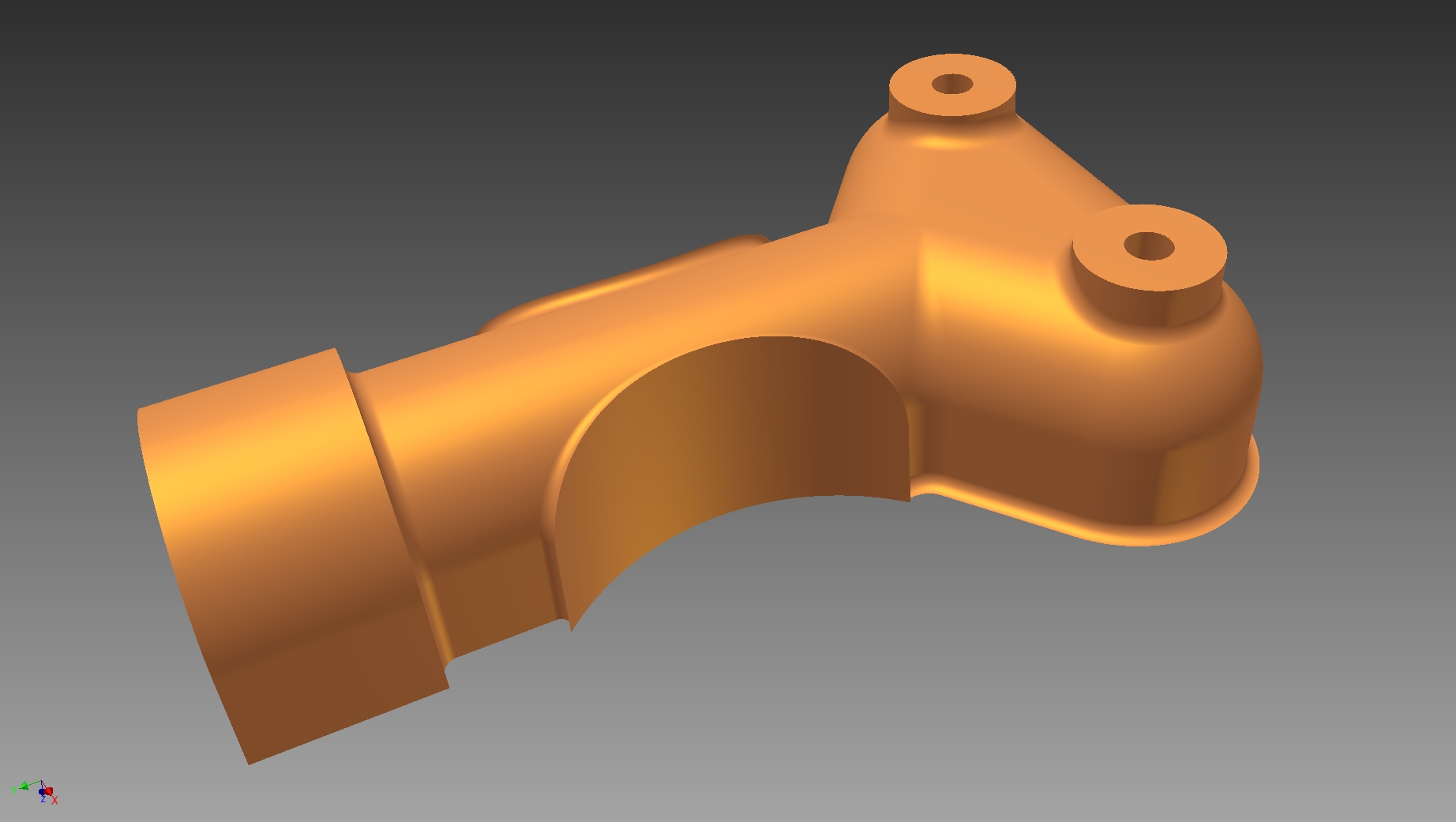

3D printers use what is called additive technology i.e. adding material where it is required. This is the reverse of traditional machining processes, which are now generally termed subtractive technology, i.e. removing material as in drilling, milling, etc. PEA provides a 3D printing service to existing engineering and drafting customers, and see’s this service as a natural extension to the traditional design process. The in-house 3D printer uses the FDM method which stands for fused deposit modelling. The printers consumable material is a product called PLA which stands for Polylactic Acid which is a thermoplastic aliphatic polyester made from natural and renewable materials, most commonly corn starch.