With the upcoming Cokemaking Coal Yard Barrel Reclaimer shutdown, an investigation was conducted to look at possible options to transfer material when the barrel reclaimer will be out of action.

Project Investigation commenced on the 31st of July 2014

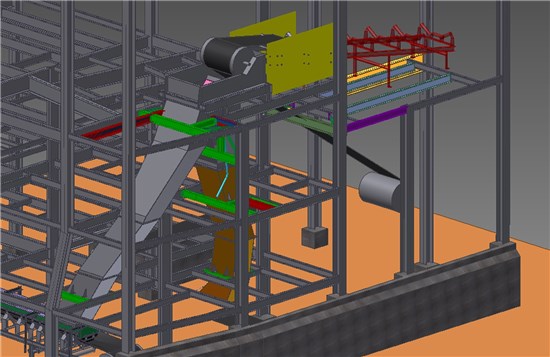

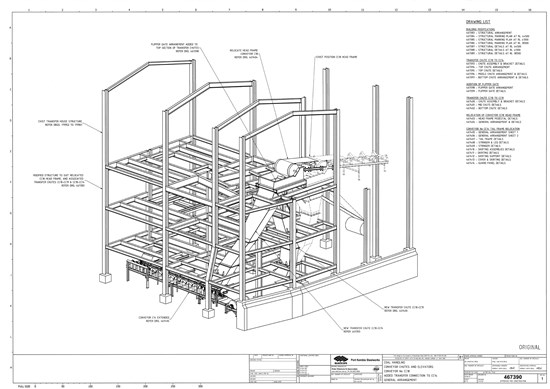

Derek Longley located in the BSL Central Engineering Office investigated the option of relocating the head of conveyor CC18, to allow for the installation of a diverter gate and a bypass chute to both CC14 and CC19 conveyor. The tail end of CC14 tail to be extended to reach the new by-pass chute. The project concept was developed from an existing model using Inventor 2014.

Project Approval was given on the 29th of August 2014

It was decided that this project had significant cost saving and that we needed to proceed at warp speed.

A few phone calls were made and the project team was assembled within the hour with 4 well regarded Inventor Drafters.

Due to Derek’s work commitments the project coordination was handed over to Zis Anastas who is also located in the BSL Central Engineering Office.

The project was broken up to manageable packages.

- Zis Anastas (BSL Central Eng Office)

- Developed Inventor Model

- Conveyor CC18 Head Relocation

- Chute Diverter Gate

- Derek Longley (BSL Central Eng Office)

- Conveyor CC14 Tail Extension

- Ken Nakken (PEA Wollongong Office)

- Transfer Chute CC18 to CC14

- Peter Weir (PEA Wollongong Office)

- Building Steelwork Modifications

- Transfer Chute CC18 to CC19

- Paul van Ryn (BSL Central Eng Office)

- Drafting Checker

Project Design and Drafting Completion was achieved on 19th of September 2014

Within 3 weeks the team produced 30 drawings at just over 300hrs (10 hours per drawing)

This included concept development, Inventor modelling, production of detail drawings and checking.