Air Mist Compressor Replacement

With number 2 air mist compressor retired due to a fire, and the three remaining compressors reaching the end of their practical lives, the time had arrived to replace this crucial plant infrastructure vital to the slab making process.

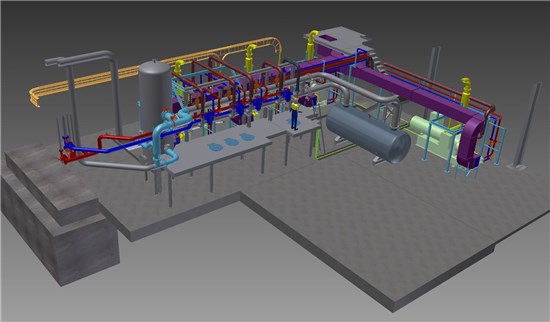

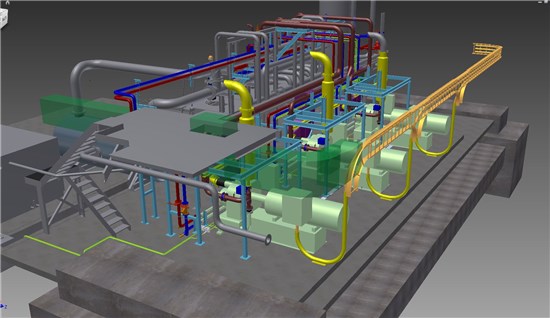

The existing compound with all equipment was modelled up, to provide the base for the staged design and installation of the four new compressors. Production requirements dictated that Compressed air had to be made available throughout the life of the replacement project.

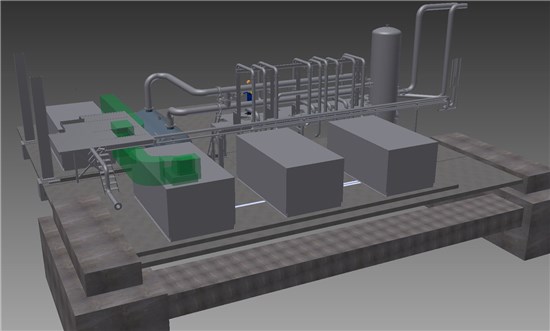

The retired fire damaged compressor number 2 is replaced and interconnecting pipework completed, restoring full capacity, allowing the next compressor to be brought offline for replacement.

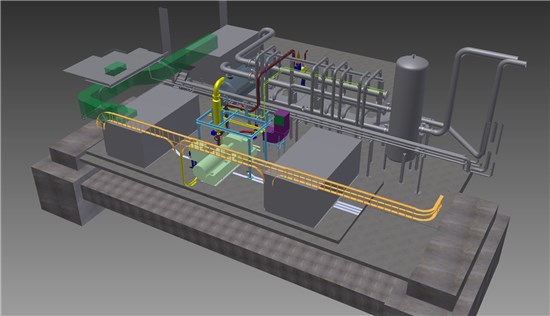

Compressor number 1 is replaced.

Compressor number 3 is replaced.

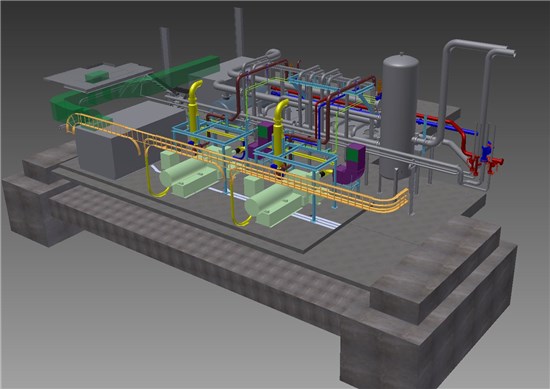

Compressor number 4 is replaced and all permanent supply ducting and discharge piping is completed.